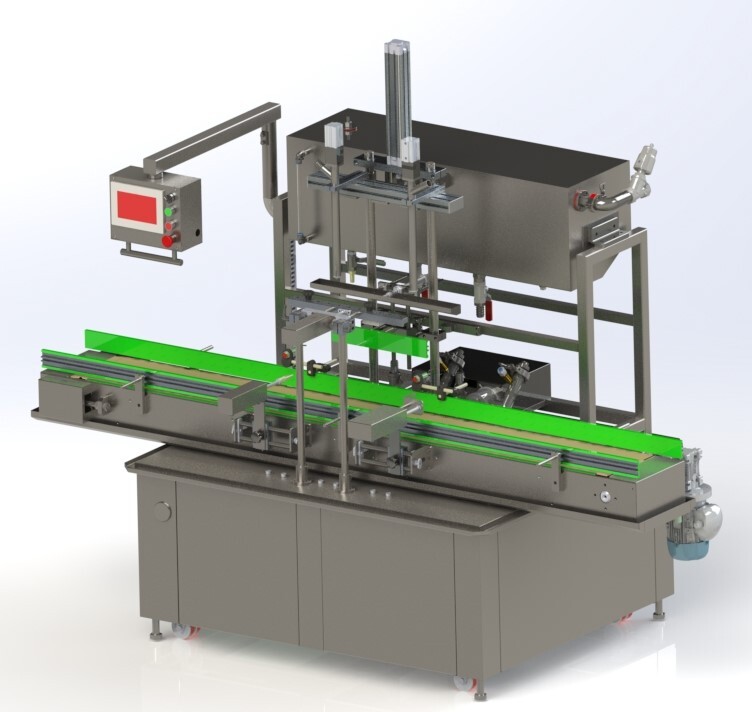

LINEAR SERVO BASE FILLING MACHINE

280000 INR/Unit

Product Details:

- Product Type AUTOMATIC SERVO FILLING MACHINE

- Material STAINLESS STEEL

- Computerized Yes

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Voltage 440 V Volt (v)

- Click to View more

X

LINEAR SERVO BASE FILLING MACHINE Price And Quantity

- 1 Unit

- 280000 INR/Unit

- 700000.00 - 700000.00 INR/Unit

LINEAR SERVO BASE FILLING MACHINE Product Specifications

- Electric

- Automatic

- 440 V Volt (v)

- STAINLESS STEEL

- 1 YEAR

- Human Machine Interface

- AUTOMATIC SERVO FILLING MACHINE

- Yes

- 400-500 Kilograms (kg)

- 20 to 120 BOTTLE PER MIN Pcs/hr

LINEAR SERVO BASE FILLING MACHINE Trade Information

- Cash in Advance (CID)

- All India

Product Description

A Servo base Filling Machine uses servo motor technology to control the filling process with exceptional precision and consistency. These machines are ideal for filling a wide range of liquid viscosities, from thin liquids to thick creams. They are widely used in industries like pharmaceuticals, cosmetics, food and beverages, and chemicals.

Construction and Design

Material of Construction : SS304/SS316 for hygienic and durable operation.

Control System : PLC-based with a touchscreen HMI for precise control and monitoring.

Programmable filling parameters for different liquid types.

Filling Mechanism : Servo motor-driven pumps ensure precise volume control.

Drip-free nozzles to prevent spillage.

Optional diving nozzles for foaming products.

Conveyor System: Adjustable speed conveyor with container sensors.

Power Supply: 220V/380V, 50Hz/60Hz, single-phase or three-phase.

Features

High Precision and Consistency: Servo technology ensures repeatable and accurate filling volumes.

Flexibility: Suitable for a wide range of liquids and container sizes.

Quick changeover between products.

User-Friendly Interface: Touchscreen controls allow easy adjustments and recipe storage.

Low Maintenance:Durable construction with minimal wear-and-tear components.

Optional Add-ons:Bottle capping, labeling, and nitrogen flushing integration.

Clean-in-Place (CIP):Easy cleaning for maintaining hygiene standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ATUL PHARMA TECH.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS