BARRAL FILLING MACHINE

150000 INR/Piece

Product Details:

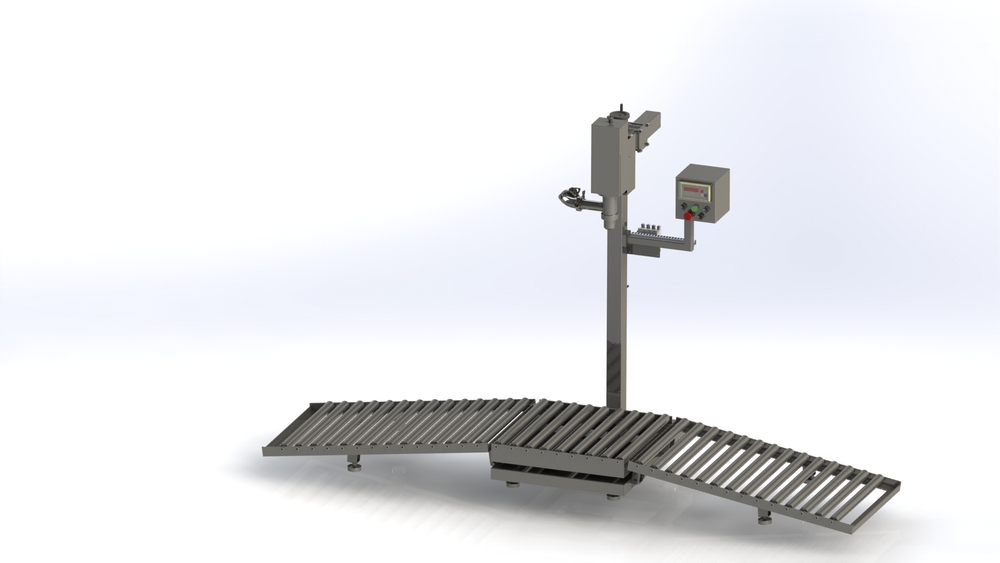

- Product Type WEIGHING FILLING MACHINE

- Material STAINLESS STEEL

- Application Chemical Food Medical

- Computerized No

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Drive Type Pneumatic

- Click to View more

X

BARRAL FILLING MACHINE Price And Quantity

- 150000 INR/Piece

- 1 Piece

- 150000.00 - 200000.00 INR/Piece

BARRAL FILLING MACHINE Product Specifications

- No

- AS PER MODEL Gram (g)

- 1 YEAR

- PLC Control

- 5 TO 50 Kg

- High Performance Low Noise High Efficiency Stable Performance Simple Control

- Chemical Food Medical

- 240 V Volt (v)

- Semi-Automatic

- Pneumatic

- AS PER MODEL Centimeter (cm)

- STAINLESS STEEL

- WEIGHING FILLING MACHINE

BARRAL FILLING MACHINE Trade Information

- Cash in Advance (CID)

- 2 Piece Per Week

- 2 Week

- All India

Product Description

-

Filling Range:

- Suitable for filling 5 kg to 50 kg (or as per requirement).

-

Weighing-Based Filling:

- Equipped with a highly accurate load cell system to ensure precise filling.

-

Nozzle System:

- Anti-drip design to prevent spillage.

- Adjustable nozzle height to accommodate different drum sizes.

-

Control System:

- Semi-automated operation with start/stop controls.

- User-friendly interface for weight setting and monitoring.

-

Material of Construction:

- Stainless steel (SS304 or SS316) for durability and corrosion resistance.

-

Tare Functionality:

- Automatically tares the drum weight for accurate net filling.

-

Compact Design:

- Space-saving design suitable for medium-scale production facilities.

-

Power Supply:

- Operates on standard single-phase or three-phase electricity.

-

Operation

- 1) Place the empty drum on the weighing platform.

- 2) Set the required filling weight via the control panel.

- 3) Position the nozzle for filling and initiate the process.

- 4) The machine fills the drum to the set weight and stops automatically.

-

Applications

- 1) Chemicals and solvents

- 2) Edible oils and lubricants

- 3) Paints and coatings

- 4) Detergents and cleaning agents

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

ATUL PHARMA TECH.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS